Cast Iron Motor End Cover

Product origin Donggang, Dandong, Liaoning province

Supply capacity 10000 tons/year

1. Cast Iron Motor End Cover is made of high-strength cast iron material, which can provide relatively stable protection and effectively ensure the normal operation of the motor.

2. The structure of Cast Iron Motor End Cover has enough rigidity and strength to resist the vibration and load of the motor.

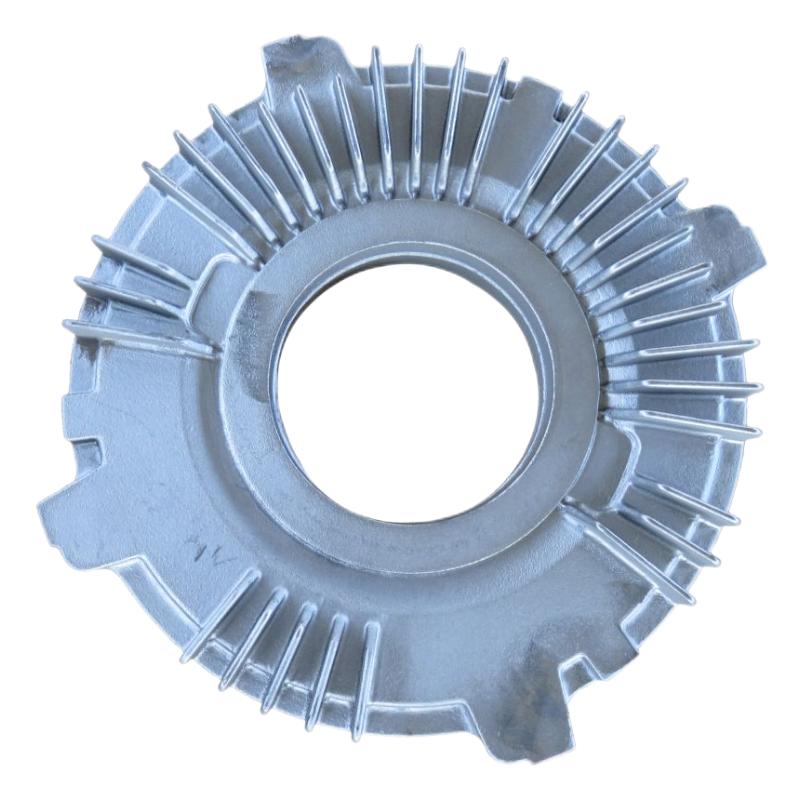

3. Cast Iron Motor End Cover has good heat dissipation performance, which can effectively dissipate the heat generated inside the motor when it is running.

Introduction of Cast Iron Motor End Cover:

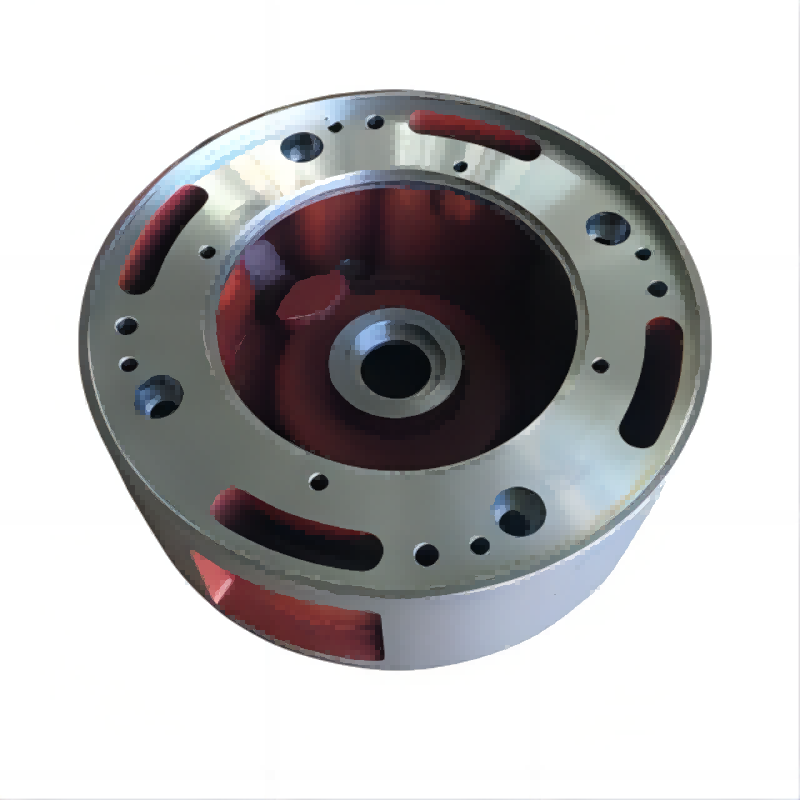

Cast Iron Motor End Cover is a type of motor housing casting.

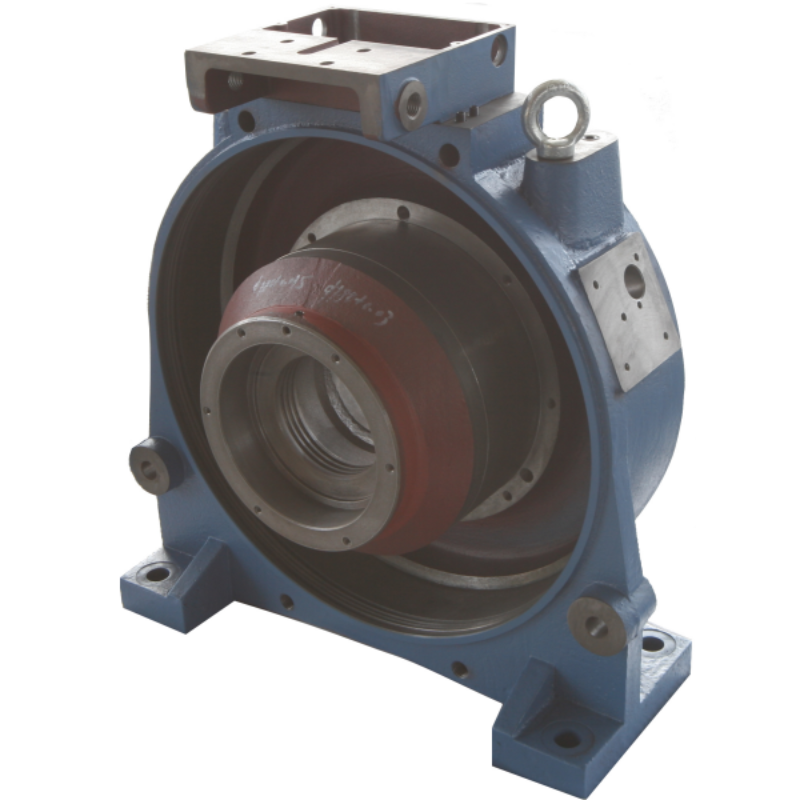

The motor end cover is the cover of the motor casing. It is generally divided into a front cover and a rear cover, which are used to close the internal structure of the motor. Cast iron is generally the main material for manufacturing the motor end cover . Motor housing casting can fix the internal parts of the motor and protect the internal parts of the motor. The main function of Motor end cover gray iron castings is to determine the spatial position of the rotor shaft, and it needs to cooperate with different types of bearings. As a type of motor housing casting, Cast Iron Motor End Cover connected to the shell of the fixed motor stator through the end cover to ensure the gap between the rotor and the stator. Motor castings usually include structures such as wire outlets and wire inlet bearing housings. The material of cast iron can play an important role in extending the service life of cast iron motor end covers.

Advantages of Cast Iron Motor End Cover:

1. As a type of Motor castings, Motor end cover gray iron castings can effectively protect the internal components of the motor. The rotor and winding of the cast iron motor end cover can prevent impurities such as external dust and water vapor from entering the motor , which will affect the normal operation of the motor.

2. As a type of electric motor casting, Motor castings can provide fixing and connection interfaces, with mounting bolt holes or threaded holes, which can be used to fix the connection between the motor and other equipment, so that the motor can work in conjunction with other equipment.

3. As a type of Motor castings, Electric motor casting can be customized according to the size you provide, and there will be no situation where the motor housing casting and your equipment cannot be covered.

4. As a type of Motor castings, Cast Iron Motor End Cover is a high-quality motor housing casting.

The scope of application of Cast Iron Motor End Cover:

Motor end cover gray iron castings can be applied to different types of machinery, including but not limited to the following:

1. Electric motor casting of Motor: Motor housing casting is an important part of the motor. It is used to seal the internal components of the motor and play a role in supporting and fixing the motor.

2. Pumps of Motor castings: Motor castings can be applied to various pumps, such as centrifugal pumps, gear pumps, etc., to protect the internal parts of the pump.

3. Fan of Motor castings: Electric motor casting can be applied to various types of fans, including centrifugal fans, axial flow fans, etc., to seal the internal components of the fan and provide support for the fan.

4. Compressor of electric motor casting: Motor housing casting can be applied to various types of compressors, including screw compressors, piston compressors, etc., to seal the internal components of the compressor and provide support for the compressor.

Notes for Cast Iron Motor End Cover:

1. Pay attention to cleaning when installing motor end cover gray iron castings. You can use solvent or clean water to remove rust and other dirt.

2. When installing electric motor casting, it is necessary to prevent violent collision, which may cause damage to the cast iron motor cover.

3. After the Motor castings have been running for a period of time, they should be checked regularly and lubricated to prolong their service life.

4.Motor castings can maintain stability.

Frequently asked questions about Cast Iron Motor End Cover:

Q1: How do you guarantee the accuracy of the size?

A1: We have a professional testing department to ensure that the size of each product meets the requirements.

Q2: Are you a trader or manufacturer?

A2: We are a manufacturer who can provide you with private customization services, and we have a dedicated factory for product production.