Complete inspection equipment and instruments

Three-dimensional coordinate measuring instrument: used to measure the size and shape of castings, and can achieve high-precision three-dimensional measurement, including length, width, height, curvature and other parameters.

Tensile testing machine is a commonly used casting product inspection equipment and instrument used to measure the tensile strength and elongation properties of materials. It can perform tensile tests on casting products to evaluate their mechanical properties and quality.

Brinell hardness tester is a commonly used metal hardness testing instrument used to measure the hardness of metal materials. In the inspection of casting products, the Brinell hardness tester is often used to evaluate the hardness and strength of the casting.

The impact testing machine is a commonly used equipment in casting product inspection equipment. It is mainly used to evaluate the impact resistance of casting products, that is, the degree of damage under impact force.

Vernier calipers are a commonly used measuring tool used to measure the size and shape of casting products. It consists of a main ruler and a sliding veneer. Vernier calipers are generally divided into two types: ordinary vernier calipers and digital vernier calipers.

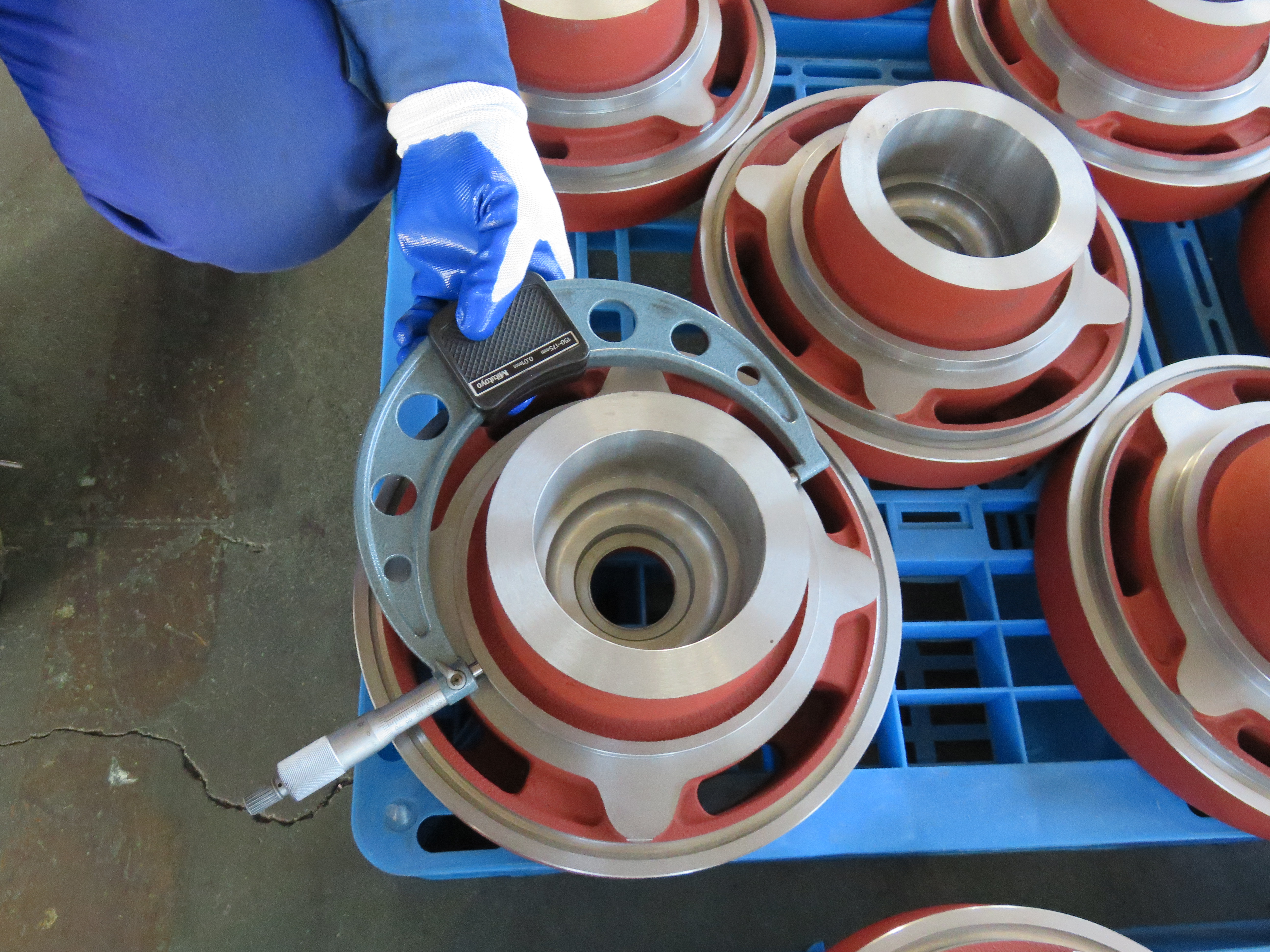

The outer diameter micrometer is a commonly used measuring tool used to measure the outer diameter of casting products. It is a precision measurement tool with high measurement accuracy and stability.

The digital Vernier caliper is an advanced measuring tool used to measure the size and shape of castings products. Compared to traditional Vernier calipers, digital Vernier calipers have higher accuracy and are more convenient to use. Digital Vernier Calipers have high measurement accuracy and can meet the precision measurement requirements for casting products. At the same time, it also has a large measurement range and can adapt to casting products of different sizes.

The metallographic analyzer is an experimental instrument used for metallographic analysis, mainly used for metallographic inspection of casting products. Metallographic analysis is to observe and analyzing the organizational structure of materials to understand its properties and quality status of materials.