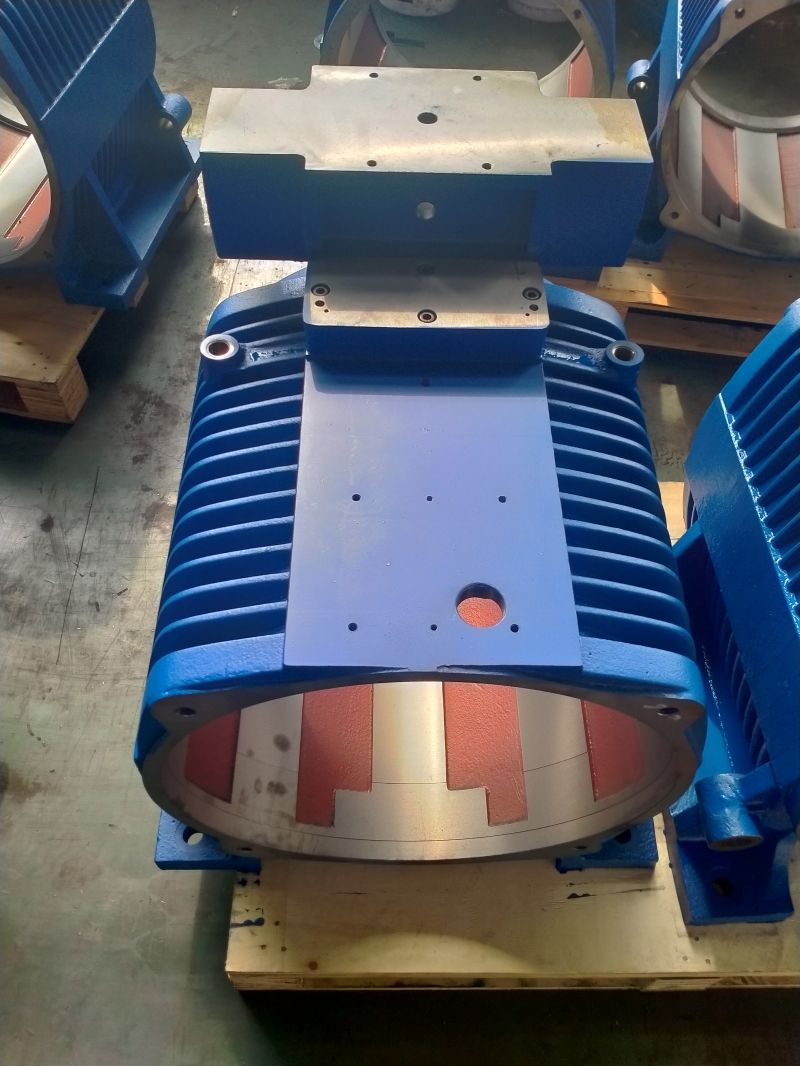

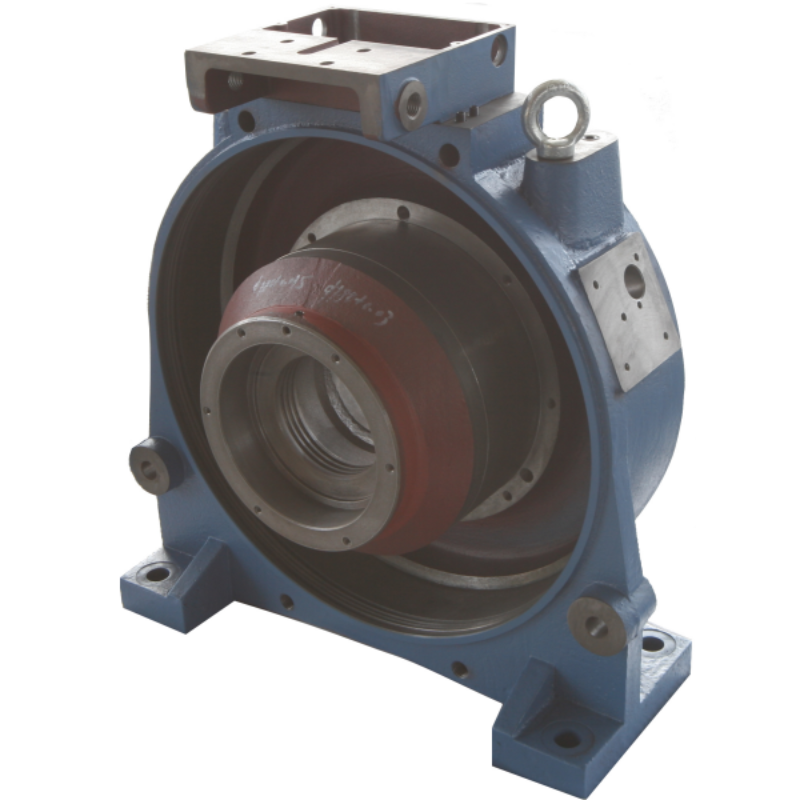

Cast Iron Motor Casing

Product origin Dandong City, Liaoning Province

Supply capacity 10000 tons/year

1. Our Cast iron motor casing is strong and durable.

2. Our Cast iron motor casing has excellent performance.

3. Our Cast iron motor casing guarantees dimensional accuracy.

Introduction to Cast iron motor casing:

Motor housing casting is a common motor component, usually made of cast iron material. Cast iron is a material with excellent corrosion resistance, wear resistance and good thermal conductivity, so electric motor casting has a long service life and good heat dissipation properties.

Advantages of cast iron motor casing:

1. Motor housing casting has good thermal conductivity and can quickly transfer the heat inside the motor, effectively reduce the motor temperature and improve the working efficiency and service life of the motor.

2. Motor housing casting has high mechanical strength and good wear resistance, can withstand large pressure and impact, and is not prone to deformation and fatigue damage.

3. Cast iron electrical motor casing can produce casings of various shapes through the casting process, which facilitates the production and manufacturing of motors.

4. The surface coating of Cast iron electrical motor casing is easy to adhere and has good anti-corrosion properties, which can extend the service life of the motor.

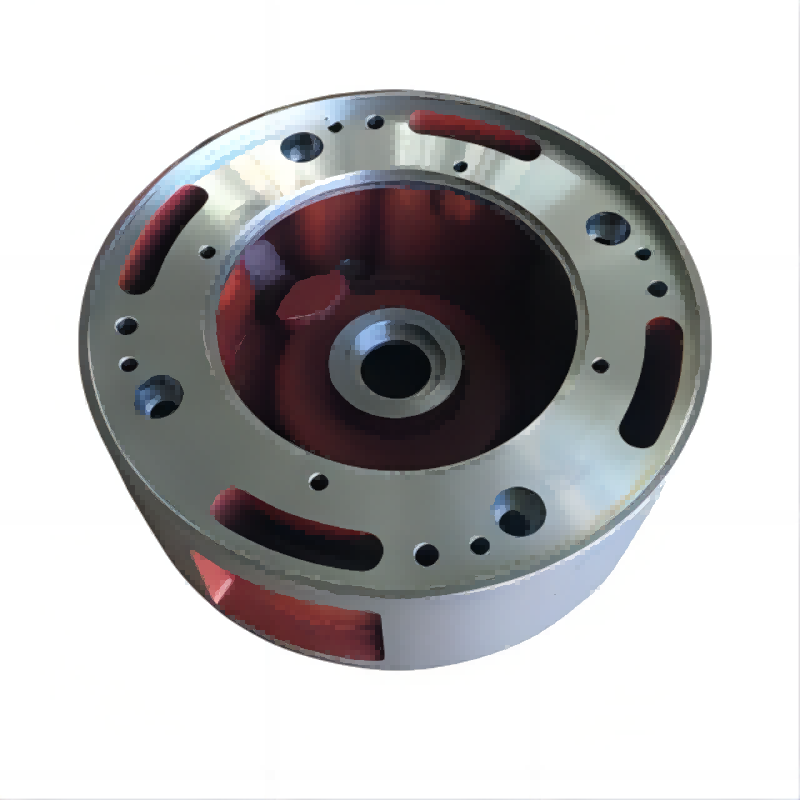

Production methods of cast iron motor casing:

Electric motor casting is generally produced by sand casting or lost foam casting. According to different motor models and uses, the shape and size of the housing are also different. The advantages of electric motor casting include good durability, high strength and excellent seismic resistance. At the same time, its manufacturing process is mature and the cost is low, so it is widely used in various motor equipment.

Why choose us?

Our motor housing casting is a reliable, durable and low-cost motor component suitable for a variety of motor equipment manufacturing and applications.