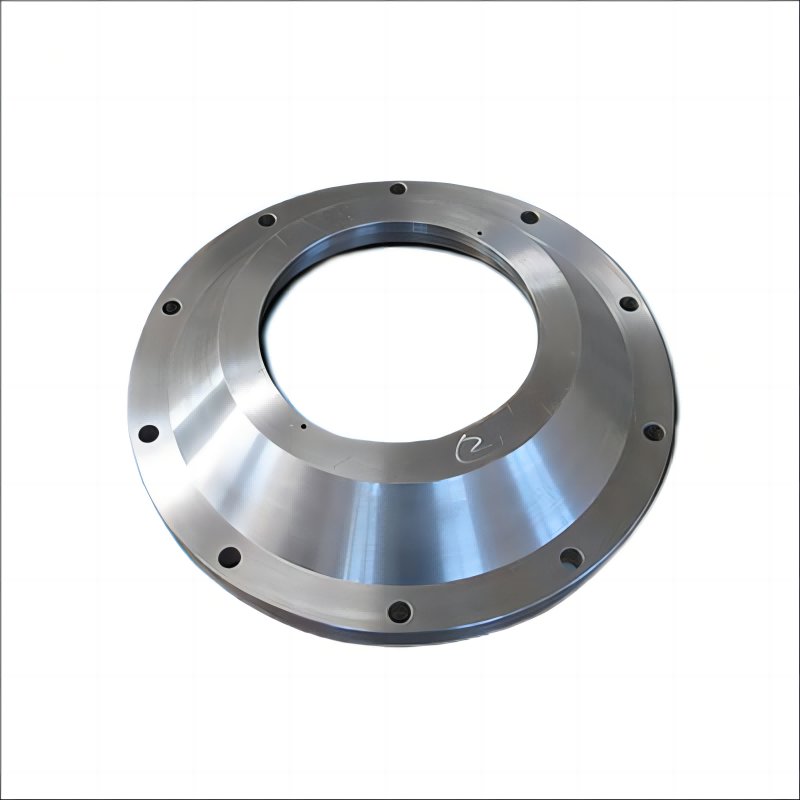

Turntable Steel Castings

Product origin Donggang, Dandong, Liaoning province

Supply capacity 10000 tons/year

1. Turntable Steel Castings' durable and long-lasting cast steel construction ensures reliable performance for heavy-duty rotating needs.

2.Turntable Steel Castings can bear a lot of weight and are ideal for supporting larger or heavier objects during rotation.

3. The solid and reliable design of Turntable Steel Castings ensures stability and safety during use and reduces the risk of accidents.

Introduction of Turntable steel castings:

Slewing table refer to casting steel into parts with rotary function by casting process. Cast steel rotary bearing can be applied to slewing table. Turntable steel castings are usually used in mechanical equipment, such as slewing table, rotary shaft and other components, to realize the rotary function of mechanical equipment. Cast steel turntable usually has high strength and wear resistance, can withstand large load and friction, and is used to support and rotate the weight of mechanical equipment. The design and manufacture of the Cast steel rotary bearing of the rotary table need to take into account its working environment and working conditions to ensure Cast steel rotary bearing stable and reliable operation.

Advantages of Turntable steel castings:

1. Cast steel turntable has excellent mechanical properties and can withstand large loads and impacts.

2. The surface of Cast steel turntable is specially treated to improve its wear resistance and prolong its service life.

3. Steel castings can be processed by special processes to make them have good corrosion resistance and can be used in harsh environments for a long time.

4. The manufacturing process of Cast steel turntable is relatively flexible, which can adapt to different shape and size requirements and meet different engineering needs.

5. Compared with other metal products, the manufacturing cost of steel castings is relatively low, which can reduce production costs.

6. Cast steel rotary bearing can be further processed and transformed through machining, heat treatment and other processes, which is convenient for personalized customization.

7. Steel castings can use a variety of different basic materials, such as carbon steel, alloy steel, etc., and the appropriate material can be selected according to specific needs.

How to use Cast steel turntable:

Place the Cast steel turntable on a stable and level surface.

Make sure the locking mechanism is disengaged or in the unlocked position.

Place the load on the turntable making sure it is centered within the diameter.

Engage the locking mechanism to secure the load in place.

Use the turntable handle or any suitable device to rotate the load smoothly.

Once the desired rotation is achieved, the locking mechanism is released and the load is removed from the turntable.

Application of Cast steel rotary bearing:

1. The slewing table can be used for workpiece transfer and positioning on the automated production line, making the production process more efficient and accurate. For example, in an automobile manufacturing plant, a turntable can be used to transfer a vehicle to the next workstation.

2. During the painting and spraying process, Cast steel turntable can be used to rotate the workpiece, so that the paint or spraying agent can be evenly covered on the surface of the workpiece, improving the coating quality and efficiency.

3. In the Cast steel rotary bearingIn the process of product assembly and assembly, Cast steel turntable can be used to rotate the workpiece, so that workers can conveniently carry out assembly and assembly operations, improving production efficiency and quality.

4. During the product inspection and testing process, the cast steel slewing table can be used to rotate the workpiece, so that the inspection equipment can comprehensively inspect all parts of the workpiece, improving the accuracy and reliability of the inspection.

Wooden box packaging and pallet packaging provide a sense of security:

Our company's freight logistics uses wooden box packaging, which has the following advantages:

① Wooden box packaging can combine products together to make the products more compact, reliable and firm. This will minimize the loss in logistics and freight transportation, ensuring the quality of the goods.

②The specifications of wooden box packaging can be unified, which saves more time for loading and unloading, reduces labor intensity, improves production efficiency, and shortens the transportation time of logistics and freight.

③Wooden box packaging can reduce the volume of packaging, save space, increase warehouse shipments, save the capacity of transportation tools, improve utilization, and further save transportation costs.