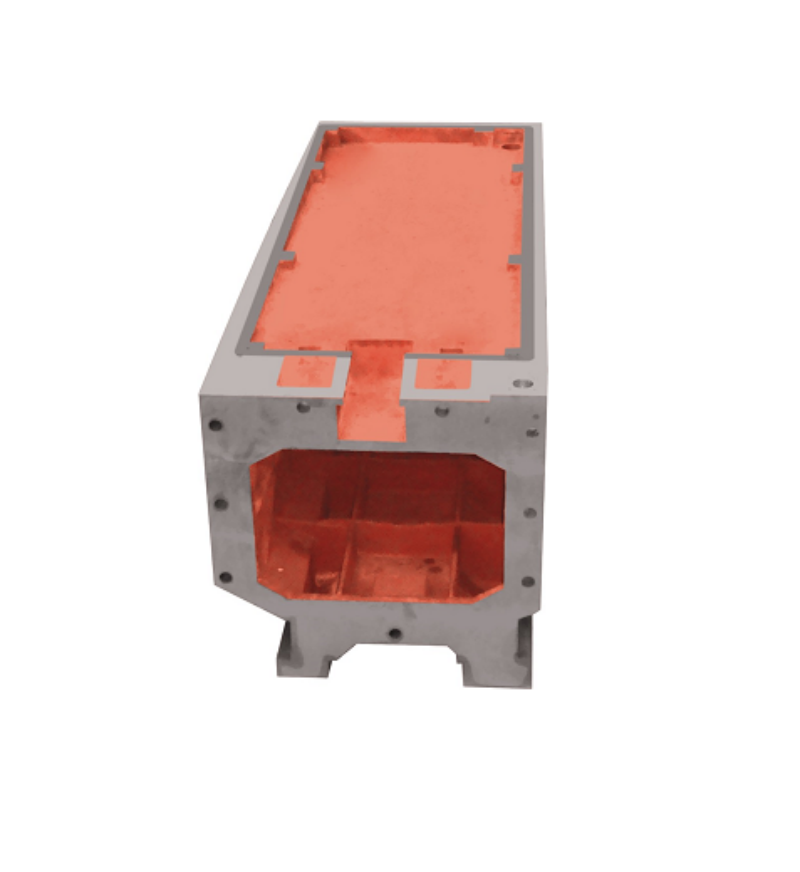

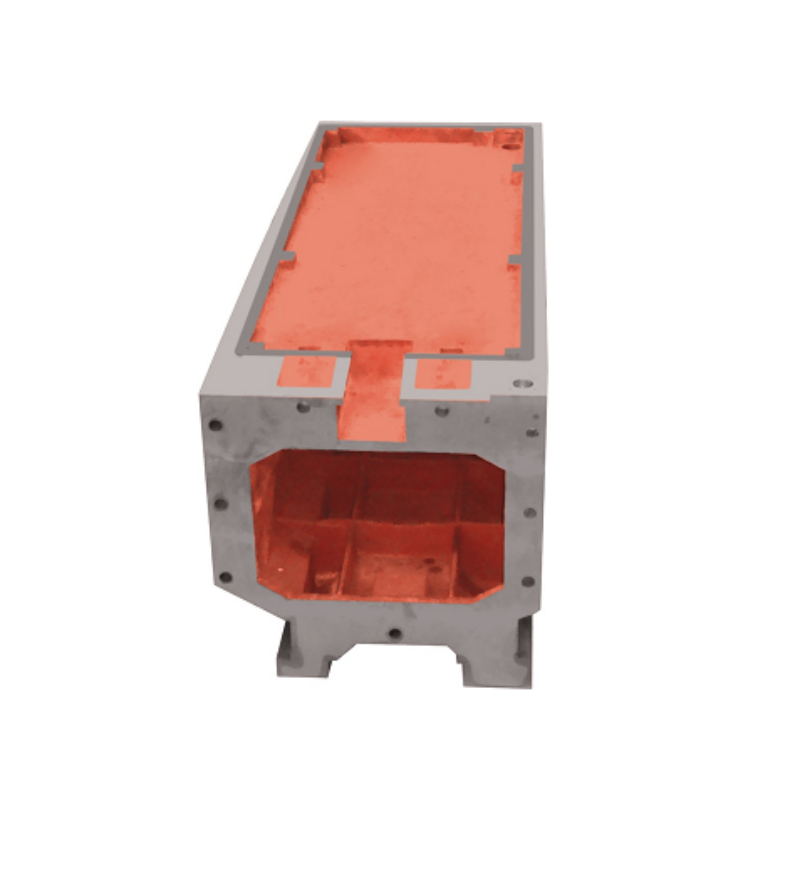

Machine Tool Bed Iron Castings

Product origin Donggang, Dandong, Liaoning province

Supply capacity 10000 tons/year

1. Machine Tool Bed Iron Castings have good wear resistance and shock absorption.

2. Machine Tool Bed Iron Castings has good process performance and is suitable for casting.

3. Machine Tool Bed Iron Castings can provide stable support for the bed of the machine tool to ensure the stable operation of the machine tool.

Introduction of Machine Tool Bed Iron Castings:

CNC machine bed iron castings is the basic base part of the machine tool structure, which can be used to support and fix the various components of the machine tool. CNC machine bed iron castings For Milling Machine usually includes ①Cast Iron Machine Bed For Milling Machine的 bed base, which bears the weight and pressure of the entire machine tool, ② Casting machine bed的column, which is the vertical support structure on the bed, ③Cast iron machine bed lathe的 beam, which connects the column to strengthen and stabilize The function of the bed structure, ④Cast iron machine bed lathe的workbench, the workbench is the mobile platform on the machine tool bed, used to install and fix the workpiece and the tool, ⑤ Cast Iron Machine Bed For Milling Machine的 slider, the slider is the moving part on the machine tool bed, used to realize the workpiece processing cutting movement. The design and manufacture of Casting machine bed should consider the rigidity and stability of the bed, so as to ensure the normal operation of the machine tool. The quality of Cast iron machine bed lathe has an important influence on the service life of the machine tool.

Pros of Casting machine bed:

1. Good material performance: Cast iron machine bed is usually made of gray cast iron or ductile iron. Gray cast iron has good rigidity and wear resistance, and is suitable for large machine tools or heavy machine tools. Ductile iron has high toughness and impact resistance. , suitable for the manufacture of small machine tools.

2. Structural rationality: The structure of CNC machine bed iron castings For Milling Machine has been optimized and designed to distribute load reasonably, reduce vibration and deformation, and improve machining accuracy and efficiency.

3. Sophisticated manufacturing: The manufacturing of casting machine bed is said to be very fine, each of which has passed strict quality inspection, no edge grinding, no rust, and high processing precision.

4. High stability: Cast iron machine bed lathe has undergone precise processing and heat treatment, and has high stability and can withstand large workloads.

Applications of Machine Tool Bed Iron Castings:

Cast iron machine bed has a wide range of applications, mainly including the following aspects:

1. Metal processing: Cast Iron Machine Bed For Milling Machine is the main tool for metal processing, it can be used for milling, drilling, boring, cutting and other metal processing operations.

2. Woodworking: Casting machine bed can also be used for woodworking. For example, woodworking machines such as planers and milling machines need bed parts to support and fix the workbench and tools.

3. Plastic processing: Cast iron machine bed lathe can also be applied to plastic processing, for example, the bed parts of injection molding machine tools are used to support and fix the mold and injection molding process.

4. Stone processing: CNC machine bed iron castings can also be used for stone processing, for example, the bed parts of stone cutting machines can be used to support and fix cutting tools and stone workpieces.

F:Are you a trading company or manufacturer?

Q:We are factory.

F:How will you control the quality?

A:We have quality control department, which will set up control plan before stating the project.

F:How can I place order?

A:You can contact us by email about your order details, or place order on line.