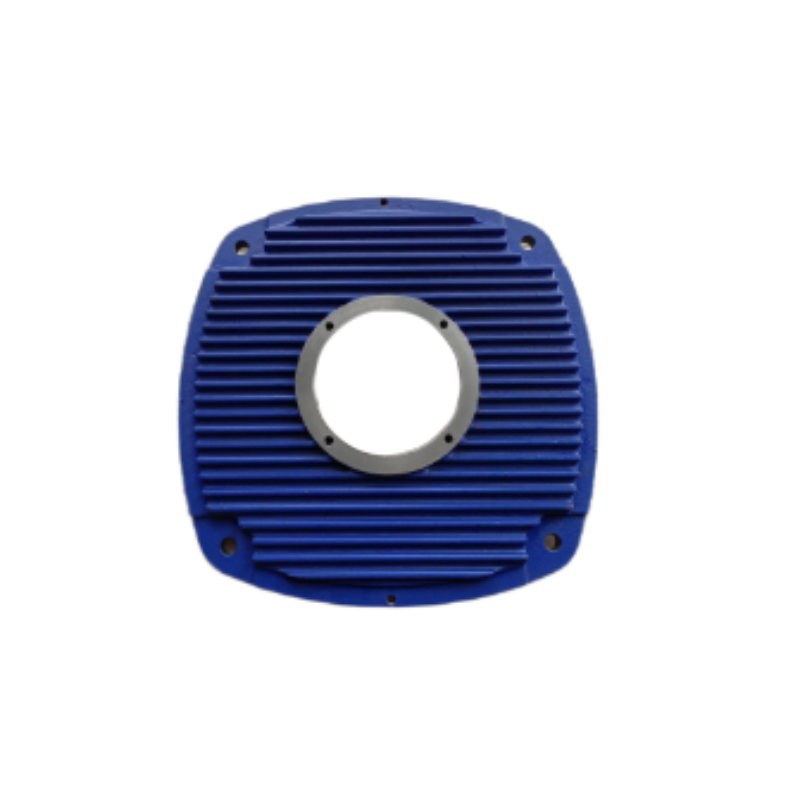

Elevator Iron Castings

Product origin Donggang, Dandong, Liaoning province

Supply capacity 10000 tons/year

1. Elevator Iron Castings supports customization, which can better adapt to the requirements of equipment or specific systems.

2. Elevator Iron Castings can ensure the safety and stability of elevator operation, and the safety performance can be improved.

3. Elevator Iron Castings are cost-effective and can reduce production costs.

Product introduction of Elevator Iron Castings:

Standard elevator castings refer to all kinds of cast iron parts used in the operation of the elevator, which can ensure the safe and stable operation of the elevator. Elevator cast iron accessories are generally used to support and connect various parts of the elevator, such as elevator machine room frame, guide rails, pit beams, load-bearing beams, etc. Elevator castings come in a wide variety, such as elevator wheel slots that carry and transmit the force of the elevator car and counterwheels; elevator guide rails that support the elevator car and counterwheels; and elevators that control and keep the doors open and closed door lock etc.

Product advantages of Elevator cast iron accessories

1. High safety performance: The production of Standard elevator castings has undergone strict quality supervision to ensure that the quality of each elevator casting is guaranteed and will not be easily damaged. During the operation of the elevator, safety can be guaranteed.

2. Low maintenance cost: Elevator cast iron accessories are made of cast iron, which has high stability and strength, and the probability of damage is very small, with a long service life and relatively low maintenance cost.

3. Private customization and high matching degree:The biggest highlight and advantage of Elevator castings is that it can accept customers' private customization. Whether it is a more common style on the market or a style that needs special customization, you can provide us with the corresponding model. Data, we can provide you with customized services, so that the elevator castings can better adapt to your equipment or system requirements.

4. Wear resistance: Standard elevator castings are made of cast iron, which has good wear resistance and can withstand long-term friction and wear, prolonging the service life of the elevator

Material selection for Elevator cast iron accessories:

Standard elevator castings generally use two types of gray cast iron and nodular cast iron. The production process of gray cast iron is relatively simple, the casting performance is relatively good, and the hardness and strength are high. Ductile cast iron is a kind of cast iron obtained by spheroidizing and inoculating molten iron so that all or most of the graphite in cast iron is spherical. Ductile cast iron has high tensile strength and good fatigue strength. Ductile iron has relatively higher requirements for craftsmanship, and the price is also higher than gray cast iron.

Frequently Asked Questions for Elevator Iron Castings:

1, How do we guarantee the quality?

We always have pre-production samples before mass production and final inspection before loading.

2. What can you buy from me?

For iron castings such as elevators and agricultural machinery, we can provide customized services according to the pictures and dimensions you provide.