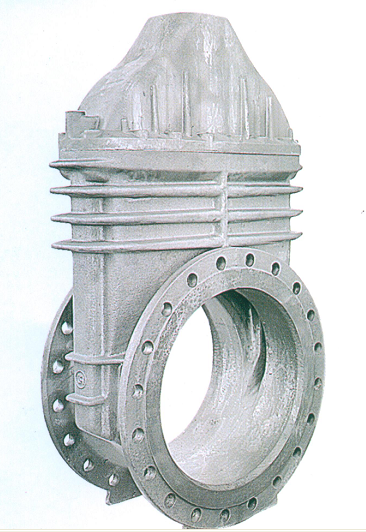

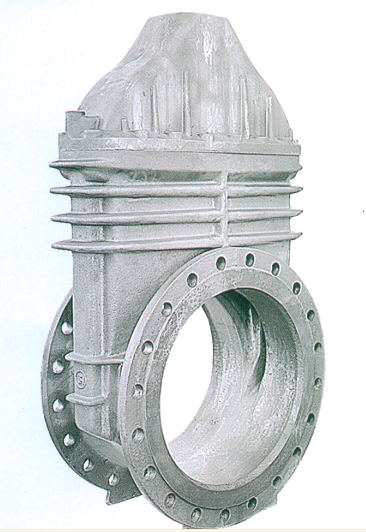

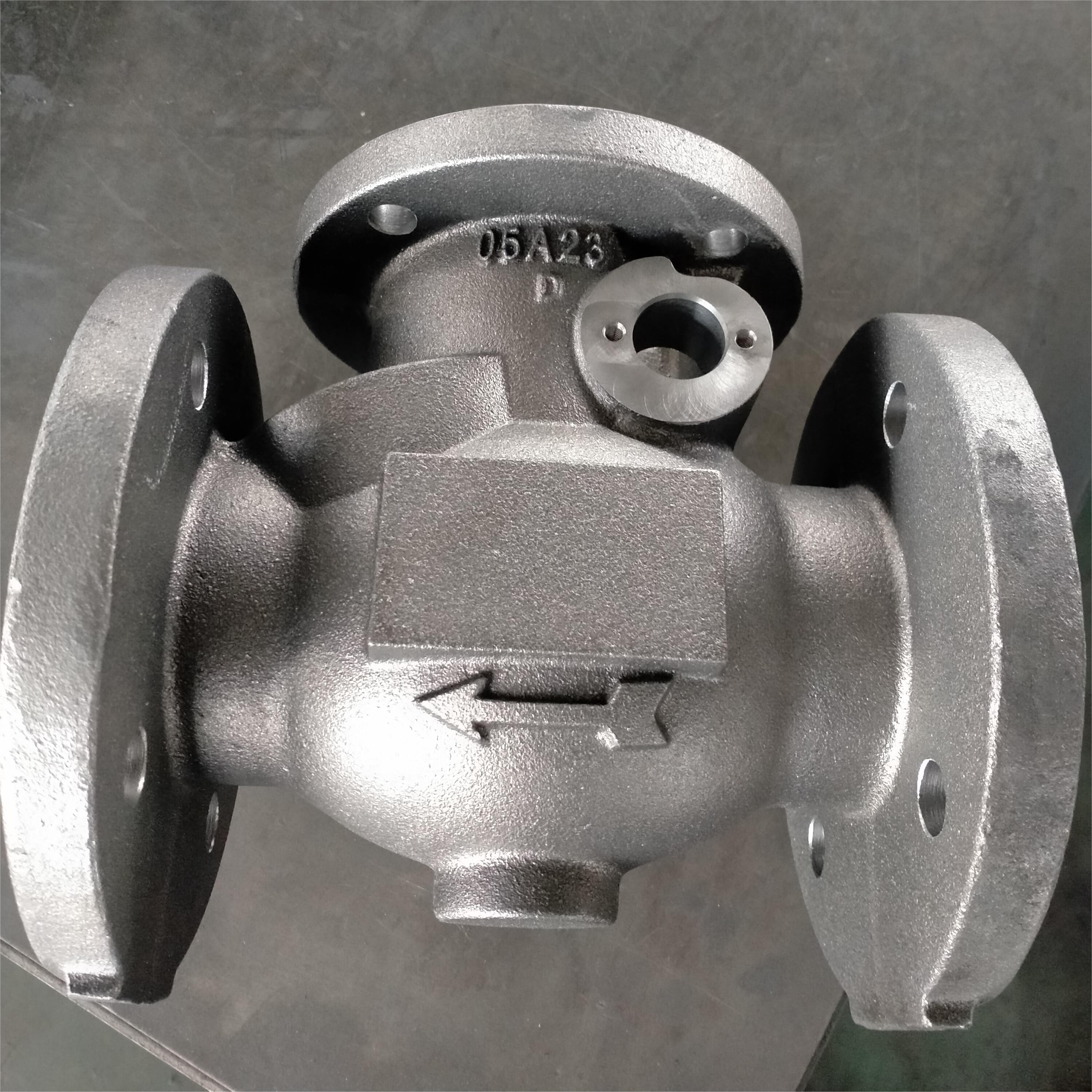

Cast Iron Gate Valve

Product origin Donggang, Dandong, Liaoning province

Supply capacity 10000 tons/year

1. Cast Iron Gate Valve has good rigidity and compact structure. With cast iron technology, the equipment lasts longer.

2. Cast Iron Gate Valve supports a wide range of pressure and temperature. Cast iron gates can support low pressure to high pressure, low temperature to high temperature, with low requirements for applicable conditions and strong applicability, and can be used in various fields.

3. The height of Cast Iron Gate Valve is high enough. The height of the gate valve is high, and the process of opening and closing the gate takes a long time, so water hammer is not easy to occur.

Introduction to Cast Iron Gate Valve:

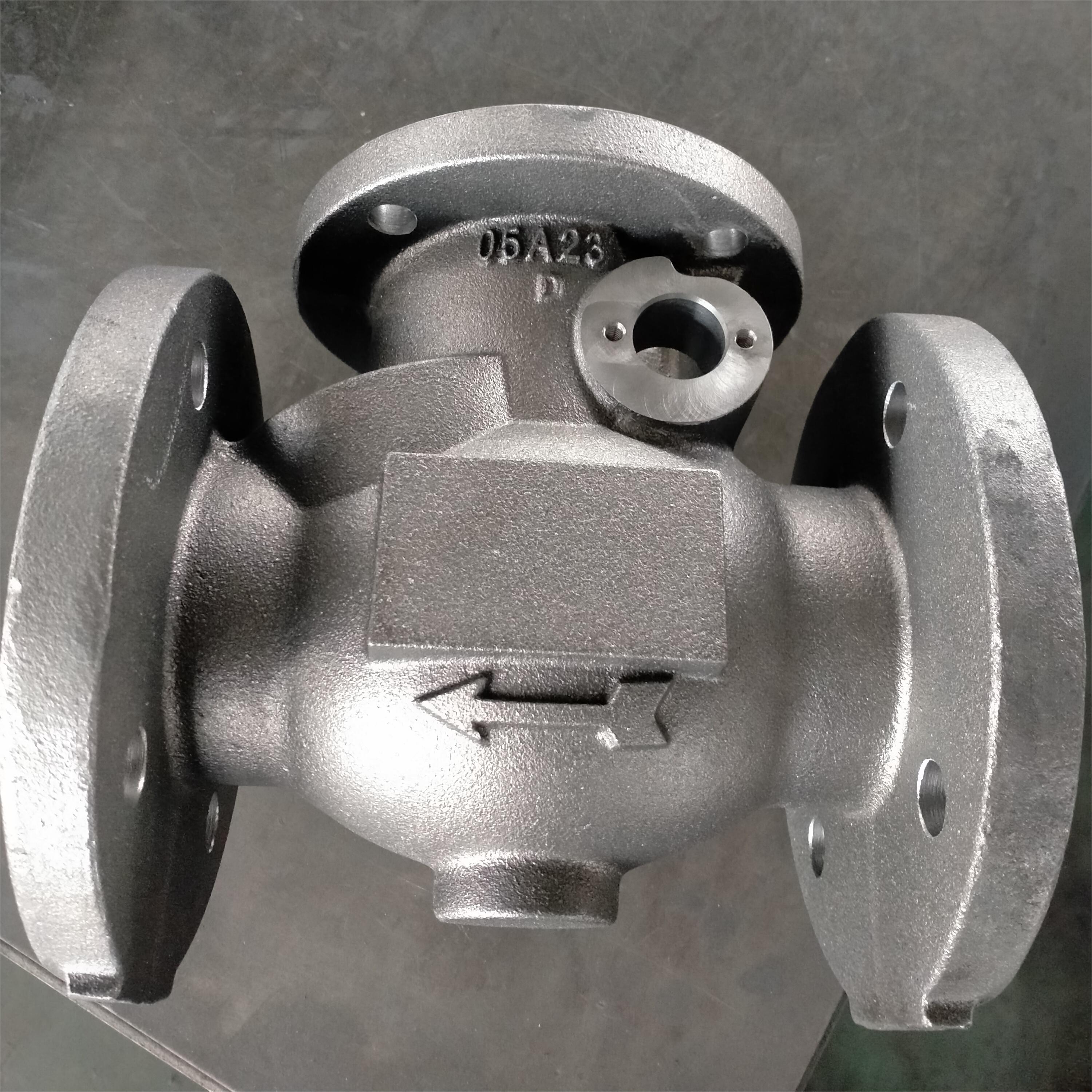

Cast iron sluice valve is a type of valve, and cast iron sluice valve is a commonly used industrial valve. Cast iron sluice valve is a type of iron gate valves. Ductile iron sluice valve is mainly used to control the fluid in the pipeline, connect the medium and cut off the medium, and fully open and fully close the flow. Iron gate valves are classified in different ways. Iron gate valves can be divided into open stem gate valves and concealed stem gate valves according to their structural forms. Iron gate valves can be divided into hard-sealed gate valves and elastic-seat soft-sealed gate valves according to the sealing surface. You can choose the cast iron flanged gate valve you need according to your work situation. Although there are many classifications of cast iron sluice valve, the working principle of cast iron sluice valve is the same, including the structure diagram of the valve.

Advantages of Cast Iron Gate Valve:

1. The cast iron sluice valve has small flow resistance. The medium channel in the valve body of iron gate valves is straight-through, the medium flows in a straight line, and the flow resistance is small.

2. The ductile iron sluice valve has a large height and a long opening and closing time. The opening and closing stroke of iron gate valves is relatively large, and the descent is performed through a screw.

3. The structural length of iron gate valves (the distance between the two connecting end faces of the housing) is small.

4. The cast iron flanged gate valve has a simple shape, short structural length, good manufacturing process, and wide application range.

5. The ductile iron sluice valve has a compact structure, good valve rigidity, smooth channel, and small flow resistance. The sealing surface is made of stainless steel and carbide, which has a long service life. It uses polytetrafluoroethylene filler, which ensures reliable sealing and light and flexible operation.

Functions of Cast Iron Gate Valve:

Cast iron flanged gate valve is usually placed at a higher place from the ground. The opening and closing gate of the gate valve moves up and down on the body of the gate valve, while the valve stem rotates. Through lifting and moving, the opening and closing of the ductile iron sluice valve is operated. close. If the product has a bypass valve, the bypass valve must be opened before opening, which can balance the pressure difference and make it easier to open the cast iron flanged gate valve.

Frequently asked questions about cast iron gate valves:

1. Can I order samples of ductile iron sluice valve?

A: Yes. We highly welcome to order samples to test and check the quality. Mixed samples are acceptable.

2. Can you OEM or ODM?

A: Yes, we have a great R&D team. Products can be made according to your requirements.

3. Can you do the design for us?

A: Yes. We can ask you to provide customized services, you only need to send us the desired size and high-resolution images, and we will make the ordered products that meet your wishes.