The Importance of Machine Tool Iron Castings in Machine Tool Manufacturing

In machine tool manufacturing, cast iron parts play a crucial role. Cast iron is a material with excellent physical and mechanical properties. Its strength, wear resistance, corrosion resistance, and low cost make it an indispensable part of machine tool manufacturing.

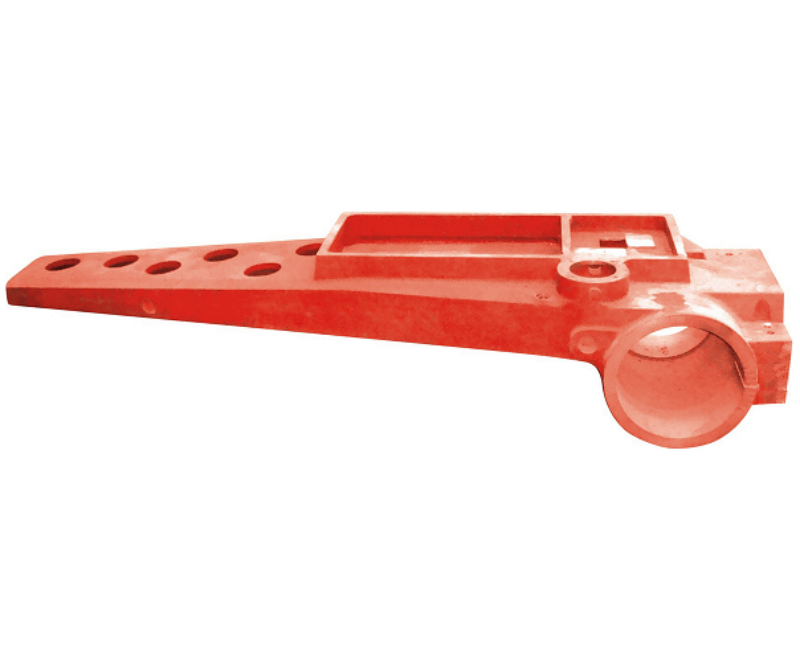

Machine Tool Iron Castings - Basic components of machine tools:

After precision casting, cast iron parts can form complex geometric shapes, such as beds, bases, workbenches, etc. These components are the basic framework of machine tools. The strength and stability of cast iron ensure the static and dynamic stability of the machine tool, improve the machining accuracy and service life of the machine tool.

Machine Tool Iron Castings - Ideal Materials for Cutting Tools:

During the machining process of machine tools, cutting tools need to withstand high-strength cutting forces, which requires materials to have excellent wear resistance. The wear resistance of cast iron parts meets this requirement, allowing cutting tools to maintain sharpness over long periods of use, thereby improving machining efficiency.

Machine Tool Iron Castings have strong corrosion resistance:

During use, machine tools inevitably come into contact with various chemicals and moisture, which requires materials to have a certain degree of corrosion resistance. The corrosion resistance of cast iron ensures that the machine tool will not be damaged due to corrosion during use, extending the service life of the machine tool.

Low cost of Machine Tool Iron Castings:

The production cost of cast iron is relatively low, which makes machine tools using cast iron parts more economical. At the same time, the large-scale production of cast iron parts also enables them to meet the requirements of various specifications and shapes, providing greater flexibility for machine tool manufacturing.