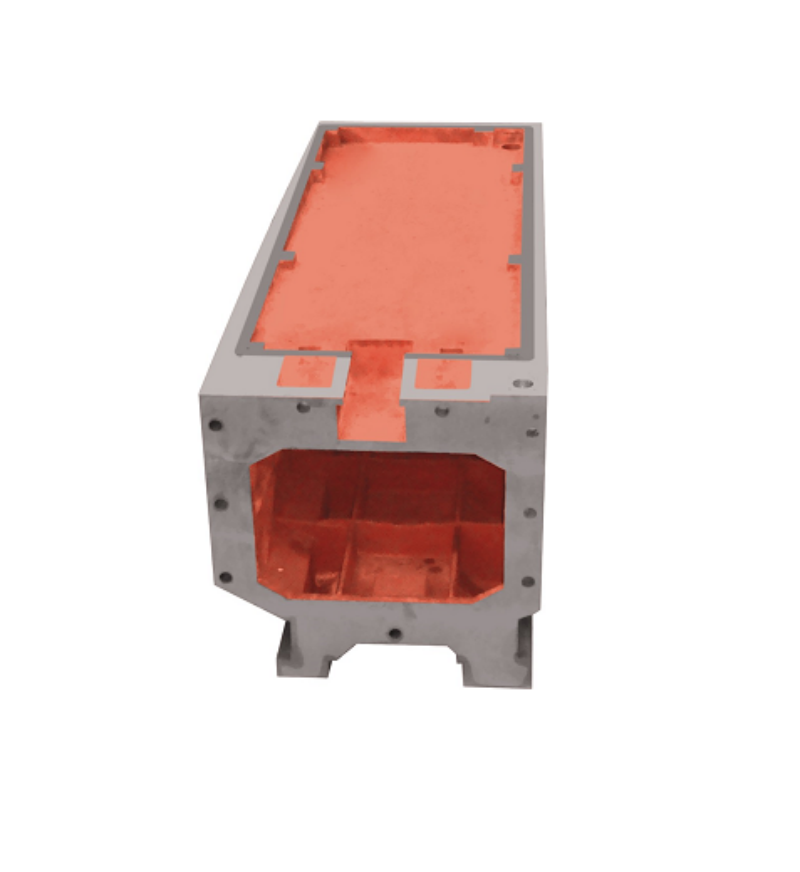

Quality Control of Machine Tool Iron Castings

In modern industrial production, Machine Tool Iron Castings are an important basic component, and their quality directly affects production efficiency and equipment performance. Therefore, quality control of Machine Tool Iron Castings is particularly important.

Selection of Machine Tool Iron Castings Materials:

Different cast iron materials have different physical and mechanical properties, such as gray cast iron, ductile iron, etc., which have their own characteristics in strength, wear resistance, corrosion resistance, etc. When selecting cast iron materials, it is necessary to comprehensively consider the actual needs and operating conditions to ensure that the selected materials can meet production requirements.

Control of casting process:

The casting process involves many aspects, such as mold design, gating system design, cooling methods, etc. Any mistake in any aspect can lead to quality issues in cast iron castings. Therefore, in the casting process, it is necessary to strictly control the process parameters to ensure that each link meets the process requirements.

Heat treatment:

By using a reasonable heat treatment process, the internal structure of Machine Tool Iron Castings can be changed, and its physical and mechanical properties can be improved. For example, quenching and tempering can improve the hardness and wear resistance of cast iron; Annealing treatment can eliminate internal stress and improve the plasticity and toughness of cast iron.

Quality inspection:

A comprehensive quality evaluation of Machine Tool Iron Castings can be conducted through methods such as visual inspection, dimensional measurement, and non-destructive testing. For unqualified cast iron parts, timely repair or scrapping is required to avoid any impact on production.