How to Check The Quality And Specifications of Cast Iron Motor End Cover When Purchasing It?

Cast Iron Motor End Cover is an important part of the motor, and its quality and specifications are directly related to the performance and stability of the entire motor. Strict inspection upon incoming goods is a key step to ensure high quality products. Here are some suggestions for checking quality and specifications when Cast Iron Motor End Cover comes in:

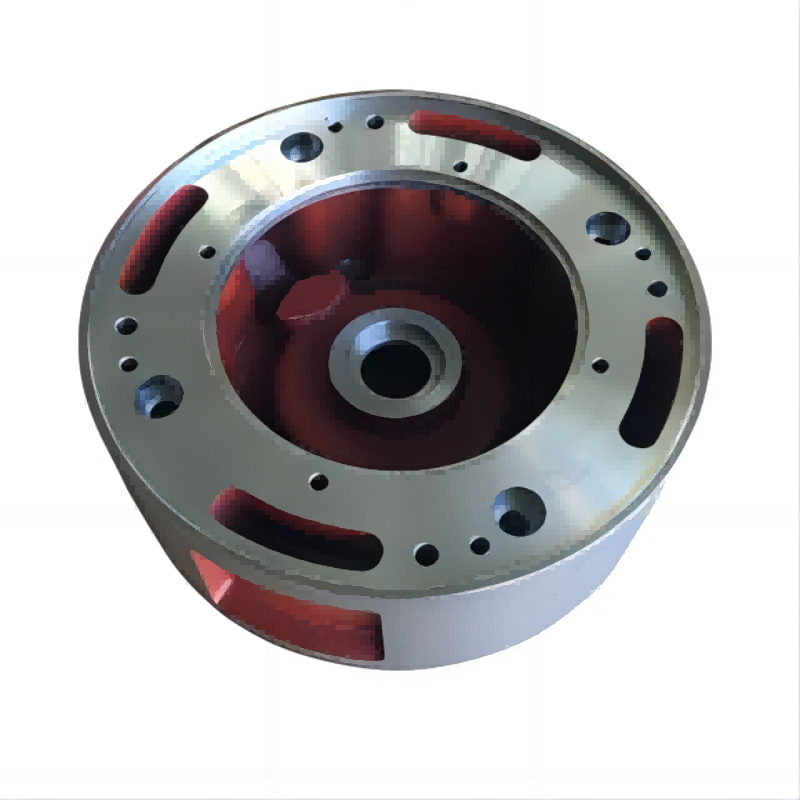

Appearance inspection and dimensional measurement:

Check that the surface of the Cast Iron Motor End Cover is smooth and has no obvious cracks, bubbles or blemishes. Make sure the exterior is evenly painted with no color difference or peeling. At the same time, use appropriate measuring tools to check whether the dimensions of the Cast Iron Motor End Cover meet the design requirements, and confirm the accuracy of key dimensions such as hole spacing, hole diameter, and wall thickness.

Material quality and surface treatment:

Confirm that the metal materials used comply with relevant international standards and industry specifications, and conduct hardness tests on the materials to ensure that they meet the design requirements. Also check surface treatments, such as anti-corrosion coatings or other surface treatments, to ensure compliance. Confirm the anti-corrosion performance to ensure the stability of the motor end cover in different environments.

Assembly performance and magnetic testing:

If the Cast Iron Motor End Cover has removable parts, check the quality of the assembly interface to ensure that no damage or deformation is introduced during disassembly and assembly. And for some motor end covers with special requirements, magnetic testing is performed to ensure that there are no magnetic defects.

X-ray detection:

When necessary, use X-ray inspection technology to check for hidden defects inside the motor end cover, such as bubbles, slag inclusions, etc.

Logo mark file certificate:

Ensure logos and logos on Cast Iron Motor End Cover are legible and comply with design and regulatory requirements. And suppliers are required to provide relevant quality certificates and test reports to ensure that products meet specifications.